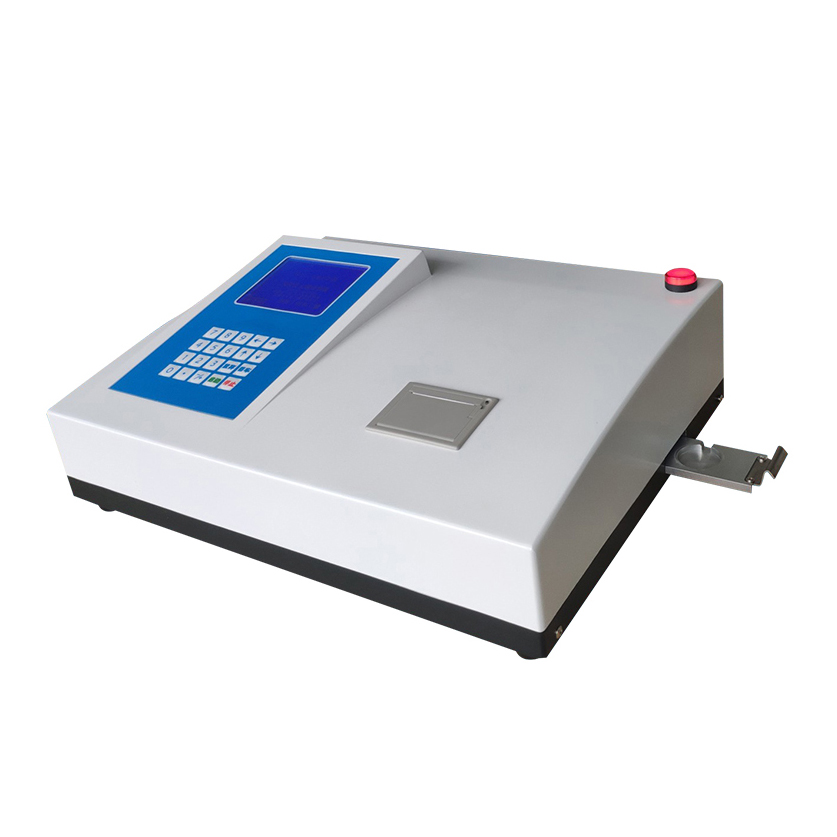

The YG6800 X-ray fluorescence multi-element analyzer is a new desktop analytical instrument that is computerized. It breaks through the limitations of domestic ordinary multi-element analyzers, which only analyze the composition of four elements: Al2O3, SiO2, CaO, and Fe2O3. It can also analyze SO3 and the amount of mixed material added. It is a five element analyzer that integrates the analysis functions of X-ray fluorescence calcium iron analyzer, silicon aluminum analyzer, and sulfur analyzer; And automatically calculate the three rate values of KH, SM, and IM. Compared with the imported large-scale X-ray fluorescence spectrometer, the analysis results are within the error range. Purchasing an X-ray fluorescence multi-element analyzer can save nearly one million RMB, with low operating and maintenance costs, and convenient maintenance.

The fluorescence multi-element analyzer adopts a large LCD screen display, with Chinese menu prompts for operation, making it easy to use; Integrated design, high degree of integration, good reliability, and easy maintenance. By using a large capacity electronic record book, more than 2000 content analysis data can be browsed, while avoiding printing consumables. Without damaging the sample, the sample can be measured repeatedly. No need for any chemical reagents, no discharge of three wastes, no radioactive sources, low power consumption, in compliance with environmental protection, energy conservation, and radiation safety requirements.

Application of X-ray fluorescence multi-element analyzer:

Mainly used for detecting CaO%, Fe2O3%, SiO2%, Al2O3%, SO3% in raw materials, clinker, cement, limestone, clay, gypsum, etc;

Detect the content of SO3%, CaO%, and admixture in cement.

In the cement industry, it is directly connected to the raw material ratio value batching control system through an RS232 serial communication port.

Technical specifications of X-ray fluorescence multi-element analyzer:

- Analysis scope: CaO, Fe2O3, SiO2, Al2O3, SO3: 0.01%~100%;

- Analysis width: CaO, Fe2O3, SiO2, Al2O3, SO3 components are all ≤ 15%, and the working range is selected by calibrating the working curve;

- Analysis accuracy: Standard deviation SCaO ≤ 0.10%; SFe2O3≤ 0.05%; SSiO2≤0.07%; SAl2O3≤0.07%; SSO3≤0.05%

- Allowable error: Δ CaO% ≤ 0.25%; ΔFe2O3%≤0.10%; ΔSiO2%≤0.20% ; ΔAl2O3%≤0.20% ; ΔSO3%≤0.15%

- Analysis time: n * 180 seconds (n=1, 2, 3, usually taken as 2);

- Stability: Absolute drift Δ CaO% ≤ 0.15%; ΔFe2O3%≤0.10%; ΔSiO2%≤0.10%; ΔAl2O3% ≤0.10%; ΔSO3%≤0.10% ;

- Usage conditions: Power supply AC 200V~240V, 50Hz; The overall power consumption is ≤ 30W; the ambient temperature is 5-40 ℃; Relative temperature ≤ 85% (30 ℃);

- Size and weight: 468mm * 368mm * 136mm, 13.8Kg.

Contact form

Contact form