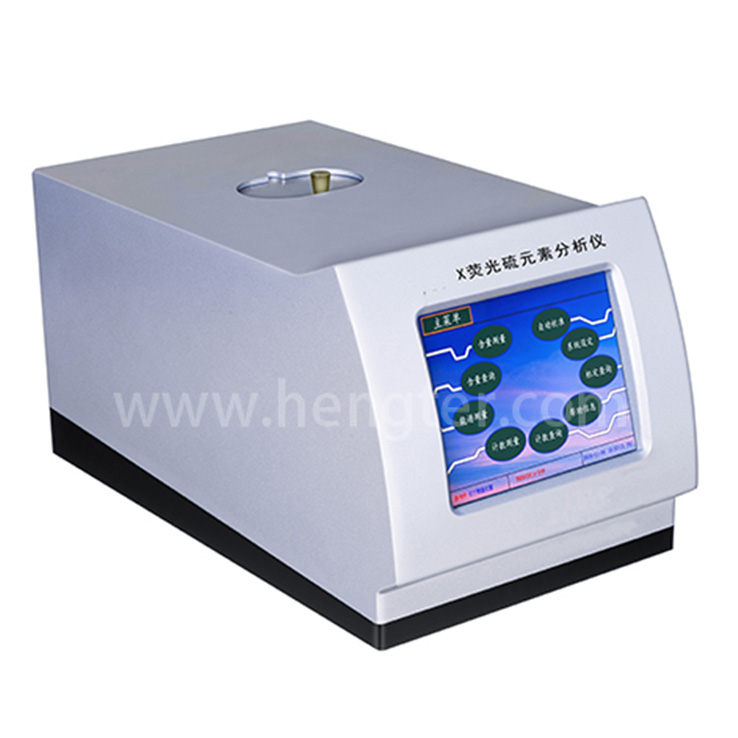

KL3300 X-ray Fluorescence Sulfur Calcium Iron Analyzer

Our company has launched an updated and upgraded product for calcium and iron analyzers, which includes one top mounted calcium and iron analyzer and two sulfur analyzers, both of which can be used before and after grinding in cement plants.

The KL3300 X-ray fluorescence sulfur calcium iron analyzer is a new type of computerized desktop instrument that uses pure physical analysis methods. Used in cement plants, it can quickly measure the percentage content of SO3, CaO, Fe2O3 in raw materials, clinker, cement, gypsum, etc. within 30 seconds. Due to its fast analysis speed, it can monitor the changes in these three components in real time during the production process, facilitating timely adjustment of raw material ratios and laying a solid foundation for the production of qualified clinker and cement. Especially when the percentage content of CaO in the finished cement is determined to be a certain grade of cement that is qualified for production by the cement manufacturer, it can create considerable economic benefits for cement enterprises by using neither excessive nor excessive clinker. Determining the percentage content of SO3 and CaO in finished cement can enable cement manufacturers to predict the strength of cement and the setting time of concrete mixed with this type of cement.

Large screen LCD display, full Chinese menu prompts for operation, intelligent error alarm prompts, extremely convenient to use.

Analysis accuracy: Standard deviation SSO3 ≤ 0.04%, SCaO ≤ 0.10%, SFe2O3 ≤ 0.05%.

Fast analysis speed, providing the percentage content of SO3, CaO, and Fe2O3 in 30 seconds.

No need for any chemical reagents, no discharge of three wastes, no radioactive sources, low power consumption, in line with environmental protection, energy conservation and safety requirements.

Technical specifications of X-ray fluorescence sulfur calcium iron analyzer:

- Analysis range: SO3, CaO, Fe2O3: The analysis range can be adjusted from 0.01% to 100%.

- Analysis range width: SO3 (CaO, Fe2O3)% max~SO3 (CaO, Fe2O3)% min ≤ 15Ca0min, selected by determining the working curve method.

- Allowable errors: SO3: ± 0.11%, CaO: ± 0.18%, Fe2O3: ± 0.10%.

- System analysis time: 30 × n seconds (n is a natural number), recommended value is 60 seconds.

- Analysis accuracy: SO3 ≤ 0.04, SCaO ≤ 0.10S Fe2O3 ≤ 0.05%.

- Temperature stability: Within the range of 5-40 ℃, absolute drift: ∣ △ SO3 ∣ ≤ 0.10 ∣ △ CaO ∣ ≤ 0.10 ∣ △ Fe2O3% ∣ ≤ 0.10%.

- Usage conditions: Environmental temperature: 5-40 ℃, relative humidity: ≤ 85% (30 ℃), power supply: 220V ± 20V, 50Hz.

- Whole machine power consumption: ≤ 50W.

- Size and weight: 468 × 368 × 136mm, 13.8kg

Contact form

Contact form