The manual tablet press is a supporting product for X-ray fluorescence sulfur, calcium iron, silicon aluminum and other analyzers. It is mainly used to press powdered samples, so that the powdered material becomes block shaped after being compressed in the sample ring, which is easy to put into the instrument for analysis. In addition, it can also be used in various production processes such as bending, punching, riveting, and assembly of parts in instrumentation hardware.

Since the early 1980s, domestic X-ray fluorescence analyzers have been used in the cement industry for more than 20 years, and their supporting products, tablet presses, have also appeared in many varieties. For example, the hydraulic tablet press originally used has gradually been eliminated from the market due to defects such as oil leakage and pressure difference; The mechanical tablet press that later replaced it still suffers from high levels of malfunctions due to structural design and production processes.

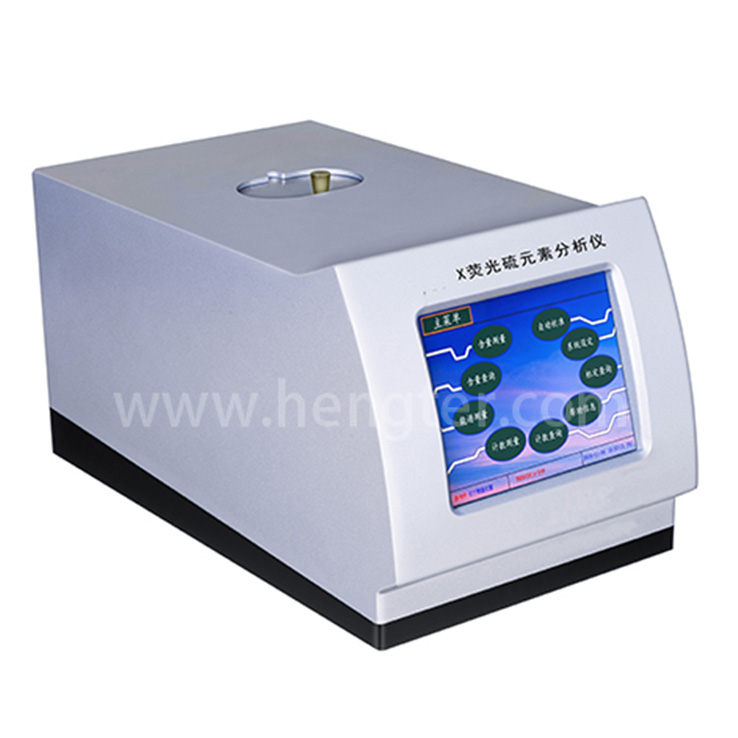

In order to solve the problem of many manufacturers using X-ray fluorescence analyzers unable to operate normally due to tablet press failures, our company has organized a strong technical backbone to develop the SKL-1 linkage manual tablet press. It has the characteristics of small size, convenient lubrication, adjustable workpiece height, easy operation, and durability. It has been widely praised by users for its “zero” failures since its launch on the market.

Main parameters:

- Final stroke: 40mm

- Work pressure: 0.5T

- Compression mold space: 125mm

- Workbench: 160mm * 160mm

- Adjustment range of mold space: 125mm ± 45mm

Contact form

Contact form