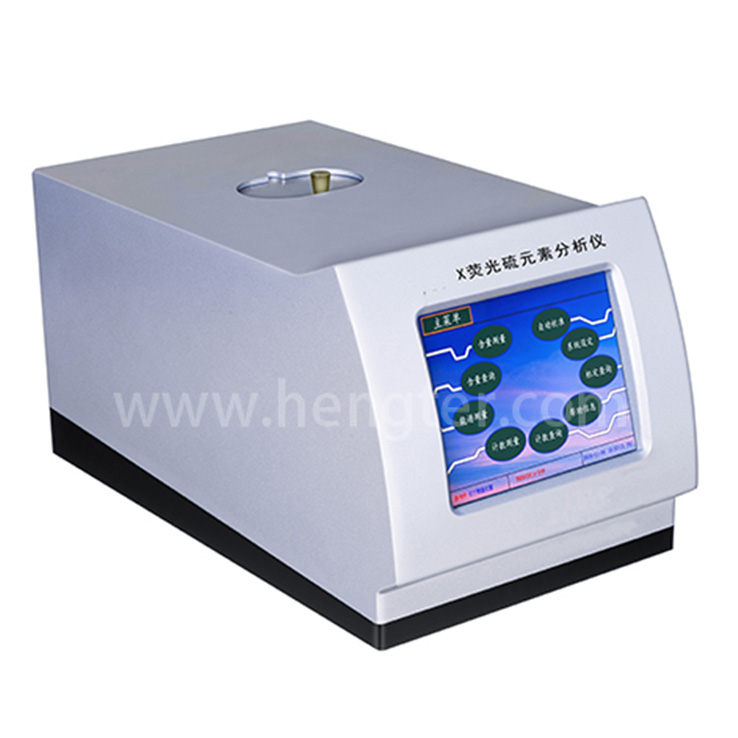

The HT3200 X-ray fluorescence sulfur calcium analyzer is specially tailored for cement plants and cement grinding station enterprises, and is an updated and upgraded product of the sulfur analyzer.

The HT3200 X-ray fluorescence sulfur calcium analyzer is a new type of computerized desktop instrument that uses pure physical analysis methods. It can detect the percentage content of SO3 and CaO in cement, gypsum, etc. within 30 seconds, and also calculate the amount of admixture in cement. By measuring the percentage content of CaO in cement, cement enterprises can predict the strength of cement and produce qualified cement of a certain grade without excessive or excessive use of clinker, which can create considerable economic benefits for cement enterprises. By quickly measuring the percentage content of SO3 in cement, cement companies can adjust the amount of gypsum added to cement in real time and predict the setting time of concrete produced with this type of cement.

Large screen LCD display, full Chinese menu prompts for operation, intelligent error alarm prompts, extremely convenient to use. No need for any chemical reagents, no discharge of three wastes, no radioactive sources, low power consumption, in line with environmental protection, energy conservation and safety requirements.

Technical indicators:

- Analysis scope: SO3, CaO; 0.01%~100%, the analysis range can be adjusted.

- Analysis range width: SO3 max CaOMin ≤ 15%. Select by calibrating the working curve.

- Inherent error: SO3: ± 0.15%, CaO: ± 0.25%.

- System analysis time: 30 × n seconds (n is a natural number), recommended value is 60 seconds.

- Analysis accuracy: Standard deviation SO3 ≤ 0.04%, SCaO ≤ 0.10%.

- Temperature stability: Within the range of 5-40 ℃, absolute drift: Δ SO3 ≤ 0.10%, Δ CaO ≤ 0.10%.

- Usage conditions: Environmental temperature: 5-40 ℃, relative humidity: ≤ 85% (30 ℃), power supply: 220V ± 20V, 50Hz.

- Power consumption of the whole machine: ≤ 30W.

- Size and weight: 468mm × 368mm × 136mm, 13.8k

Contact form

Contact form