Under specified conditions, when the oil is heated and its temperature reaches a certain level, the mixture of the oil’s vapor and the surrounding air will flash when it comes into contact with a flame. The lowest flash temperature is called the flash point value of the oil.

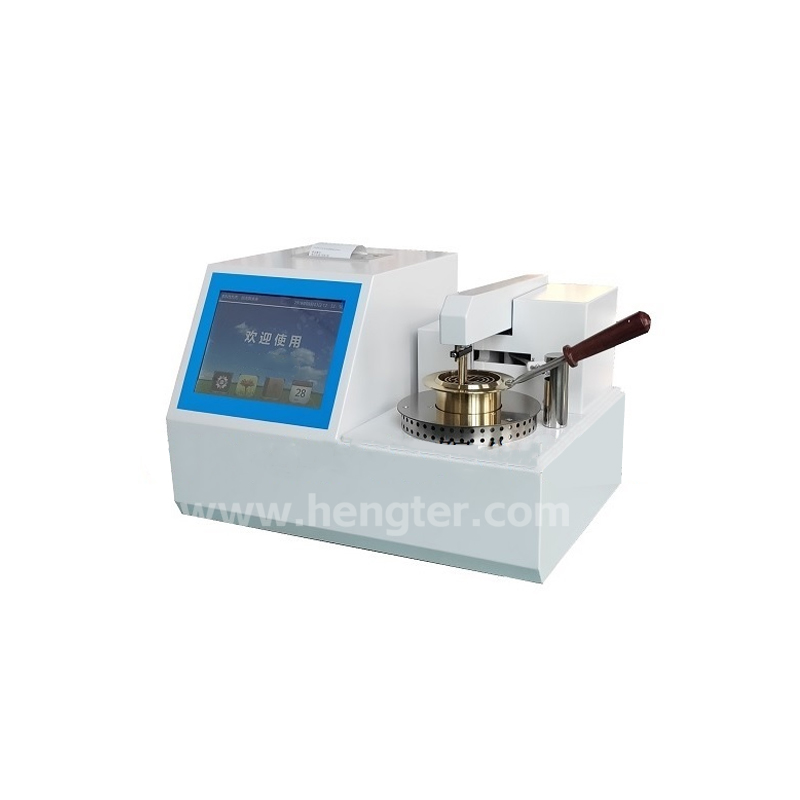

The HTBS-800 fully automatic closed cup flash point tester is manufactured in accordance with the new standard method 1 of the national standard GB/T261-2021 “Determination of Flash Point – Pensky-Marten Closed Cup Method” and the provisions of ASTMD93. It is applied in the petroleum, chemical, power, environmental protection, railway, scientific research and other departments, and is an ideal instrument for closed cup flash point testing.

Main features

- It adopts a new type of high-speed signal processor for control and an adaptive PID control algorithm to automatically adjust the temperature rise curve according to standard requirements;

- It is equipped with an automatic atmospheric pressure detection chip, which automatically measures, corrects and corrects the flash point value of atmospheric pressure;

- The automatic measurement of lifting, stirring, ignition, detection, alarm, cooling and printing instruments is completed;

- Safe and gas-free, platinum alloy electric heating wire ignition method, safe, stable and reliable, with high testing accuracy;

- Differential detection, automatic correction of system deviation, automatic stop of detection and alarm when temperature exceeds the limit;

- Both Chinese and English interfaces are available for operation. When national standards are revised, the instrument program can be upgraded;

- The optional USB interface can export data to a computer (optional), and the RS485 port communicates with the user;

- It comes with 12 sets of data temperature point corrections;

- The furnace body temperature is automatically displayed, allowing you to check it at any time for convenient sample making next time。

- It complies with the new standards of GB/T261-2021, namely 261-A, 261-B, and 261-C, and each degree test is optional。

Step A: Heat the sample at a rate of 5 ° C /min- 6 ° C /min, with stirring speeds of 90r/min—-120 r/min

Step B: Heat the sample at a rate of 1℃/min to 1.5℃/min, with a stirring speed of 250r/min±10 r/min

Step C: Heat the sample at a rate of 2.5 ° C /min- 3.5 ° C /min, with stirring speeds of 90r/min—-120 r/min

Main technical indicators:

| Display mode | 8-inch 65K (resolution 800*600) Chinese touch screen display |

| Measurement method | Thermocouple differential detection type |

| Display range | -59.9 ° C to -400 ° C |

| Measurement range | Room temperature -400℃ (If the flash point at sub-zero temperatures needs to be determined, the sample should be frozen first.) |

| Resolution | 0.1℃ |

| Repetitiveness | National standard: When the flash point value is less than 104℃, the tolerance is ±1℃; when the flash point value is greater than or equal to 104℃, the tolerance is ±2℃ International standard: When the flash point value is ≤110℃, the tolerance is ±1℃; when the flash point value is >110℃, the tolerance is ±2℃ |

| heating rate | Comply with steps A, B and C of GB/T261-2021 for each degree test |

| Printer | Low-power consumption high-speed thermal printer, 56mm paper width |

| Temperature detection | Platinum resistance (Pt100Ω) |

| Ignition method | Gasless electronic ignition |

| self checking function | Automatic diagnosis of instrument faults |

| cooling-down method | air blast cooling,forced cooling |

| External dimensions | 450X280X290 mm |

| Net weight | 15kg |

Contact form

Contact form